َAbout Nano Sciencetech

Business and Product Description

Hydrocarbons have historically been the primary energy source for civilizations for hundreds of years and still play a vital role in the day-to-day work of life. With the dramatic increase in the future rate of the human population, which will reach 9.8 billion by 2030, this will require an increase in the supply of goods and services, which can be achieved by increasing gas and oil production worldwide. In addition to oil and gas production, pipelines play an important role worldwide to transport gases and liquids over long distances from their source to their supply. There are generally three types of pipelines used in the world:

a) Collection lines for shorter distances and up to 4 inches in diameter,

b) Feeder lines that connect from oil storage to transmission lines in larger size compared to collection lines.

c) Transmission lines (maximum diameter 48 inches) are the main form of oil supply.

Pipelines exposed to the atmosphere usually reduce the problem of corrosion on its surface. Corrosion is the oxidation of a metal by an electrochemical reaction. The oxidizing agent is often O2 (atmospheric corrosion), H+ (chemical corrosion), or both. Generally, oil and gas pipelines are made of ASTM A106 B low alloy steel (Poapoola, 2013). These materials are mainly iron (98 to 99% iron), small amounts of carbon (0.001 to 0.30% by weight), manganese (0.30 to 1.50% by weight), and other intentional alloying elements added in small amounts (niobium, molybdenum, vanadium, titanium)(Kiefner, 2001). Extracting base metals from their ores requires a significant amount of energy. Because these metals are thermodynamically stable in their pure form, they tend to oxidize to lower energies, and this process is commonly referred to as corrosion (Peabody, 2001).

The boom in oil and gas trade, both in the United States and globally, has drawn attention to efforts to reduce corrosion on the surfaces of pipes and equipment used in industry.

The United States is made up of more than 2.6 million miles of gas and oil pipelines. As the main pipeline system, metal pipelines transporting gas and hazardous liquids on land require a high safety standard. Because in the oil industry, pipeline failure due to corrosion is one of the most common problems in the oil sector, especially transmission pipelines that are buried in soil or water or buried below. Hence, it is the biggest engineering and economic problem and the most widespread globally, and it is the most distinctive through the significant impact of these problems on those projects.

Fessler (2008) showed that onshore gas and liquid pipeline corrosion had cost more than $ 7 billion. One of the reasons for this is that most oil and gas pipelines are made of low-carbon steel, which means that it is vulnerable to corrosion because the main element is iron. Despite various protective coating systems that are often used as a strategy to control corrosion, there are still challenges to reducing metal corrosion.

Some common coating features for oil and gas pipelines include (Mirza, 2016):

1- Effective electrical insulation: Corrosion is an electrochemical process. A coating must block the current by separating the tube from the installed medium/electrolyte, so the coating must have strong dielectric strength.

2- Effective moisture barrier: Low water absorption level is desirable, increasing CP’s (Cathodic Protection) effectiveness.

3- Applicability: The use of the coating on the pipe must be possible in a way that does not have any adverse effect on the properties of the pipe.

4- Good adhesion to the pipe surface: Good adhesion and cohesion are critical parameters for anti-corrosion coatings.

5- Ability to carry/normal installation: The cover must protect against damage due to its impact, abrasion, and flexibility characteristics.

6- Dissolution resistance: Most CP pipelines are directly proportional to the quality and reliability of the coating.

7- Ease of repair: Field cover/repairs should be easy to do.

8- Non-toxic interaction with the environment: Coating must approve modification, restriction, or prohibition due to environmental / health standards.

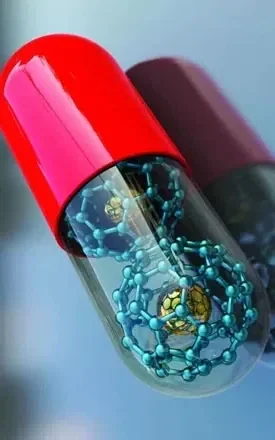

One corrosion control coating with most of the above properties is carbon nanotubes(CNTs). Carbon nanotubes are nanometer-scale tubular structures consisting entirely of carbon atoms (see Figure 1). They represent a newly discovered elemental form of carbon and have remarkable properties in terms of mechanical strength, thermal conductance, and electrical conductivity. CNTs are the most robust materials ever discovered, with tensile strengths reported to be 50 times that of steel. They can also have conductivities 1,000 times that of copper (https://www.adhesivesmag.com/articles).

Figure 1- Single-Walled Carbon-Nanotube

Source: https://www.adhesivesmag.com/articles

These coatings have increased strength and electrical conductivity due to the inclusion of carbon nanotubes while accommodating sacrificial metal particles (such as zinc, aluminum, magnesium) to inhibit corrosion through cathodic protection. These coatings can be painted using standard painting equipment (ordinary air spray and HVLP, airless spray, brush, roller, etc.) and based on traditional coating polymers, including epoxy and urethane chemistry. Carbon nanotubes allow metal-filled sacrifice primers to be formulated compared to traditional systems with much-reduced metal content.

This startup will produce pipes with CNTs coating to be used in the oil and gas industry.

2-1- Company

The founder of this company intends to start a business that produces pipes coated with CNTs suitable for use in the oil and gas industry. The practical and experimental backgrounds of the founder have led her to start working in this field.

She believes the innovations provide industry professionals with the unprecedented ability to “see” what is happening and respond in real-time. Every year, many oil and gas pipelines need to be maintained, which requires the use of various efficient methods. Due to active projects in oil, gas, and petrochemicals, maintenance of oil and gas pipelines has become one of the main concerns of the oil industry. Conventional and mechanical methods such as replacing or welding pipelines have problems, including high costs and difficult and complex operations to install the pipes, which are sometimes life-threatening.

The use of new technologies in the transportation and production of hydrocarbons is one of the priority tasks in developing regions for the modernization of industry. It strengthens the competitive advantage in the global market of fuel and energy carriers. She believes that developing environmentally friendly materials and compounds that ensure the structures’ reliability, profitability, and durability has become increasingly important. Therefore, based on her research, she considers carbon nanotubes the most profitable and cost-effective anti-corrosion coating for pipes used in the oil and gas industry and intends to produce pipes with this coating. This company has been equipped with the knowledge and expertise to produce pipes coated with CNTs.

The purposes of establishing a pipe production plant in which the pipes are coated with CNTs are:

– Making a profit by providing and selling high-quality production

– Working in an area of interest where there is work experience

– Producing pipes suitable with special coating for use in the oil and gas industry

a- Technology and Benefits

Corrosion has been a significant cause of oil/metal pipeline failure in the United States and worldwide. A report found more than 2.6 million miles of gas and oil pipelines in the United States. Most pipelines are made of low-carbon steel, and severe failure occurs when exposed to corrosive media during oil and gas transportation. Corrosion creates huge maintenance costs in the pipeline community. As of 2014, the reported cost of corrosion in the oil and gas industry was more than $ 17 billion for the United States (Abbas et al., 2018).

Although significant efforts have been made to control and reduce corrosion, the promotion of protective coatings used to prevent corrosion of oil/gas pipelines is still in high demand for high corrosion resistance and high damage tolerance.

Carbon-based nanoparticles have attracted much attention in the last two decades due to their ability to provide outstanding mechanical, tribological, and electrical properties with different dimensions and geometric shapes. Carbon nanotubes have been a focus of nanotechnology research since their discovery. Advances in synthesis technologies have now enabled the large-scale production of CNTs so that these materials find their way into commercial product applications.

Carbon nanotubes are available in various forms, including single-walled nanotubes (SWNT) and multi-walled nanotubes (MWNT). In addition, MWNTs can be manufactured with a “Russian doll” structure consisting of separate tubes in the tubes or with a “parchment” structure consisting of a continuous and multi-rolled carbon sheet. CNTs can also be based on how the sheets of carbon atoms are connected (such as “zig-zag” and “seat seats” configurations), as well as in a variety of sizes, with typical diameters of 1-3 nm and lengths that approach several microns (with aspect ratios exceeding 1,000x).

Different CNTs can show great differences in strength, conductivity, and other properties. Existing commercial CNTs usually consist of complex mixtures of pipe types and sizes, so choosing the right CNT becomes a critical requirement for successful results in a particular program.

After producing suitable pipes for oil and gas transmission in this production unit, a multi-layer composite coating is used based on polymer fibers and embedded carbon nanoparticles (CNPs). The combination of Ultra-high-molecular-weight polyethylene (UHMWPE) and hydrocarbon nanotubes (CNTs) has been shown to provide a coating for oil and gas pipes that has electrical conductivity and thermal conductivity of materials, heat resistance of the coating, mechanical properties, antistatic properties, adhesion resistance and resistance to aggressive work environments.

A CNT synthesis machine is used to produce this coating, which is a series of chambers, preheating and pyrolysis furnaces, a quartz tube, and rods immersed in a tank with water, connected in series. (Figure 2)

Figure 2- A flow diagram of the aerosol synthesis of carbon nanotubes

Source: Belov et al 2021

This process makes it possible to replace different organic carbon sources in creating CNTs. A carrier gas (argon) and a carbon-containing component (ethanol with ferrocene) enter the reactor. An ultrasonic nebulizer is used to create an aerosol that produces aerosol particles up to 3 microns in diameter. A mixture of ethyl alcohol with a catalyst is used as the carbon source. The argon current, passing through a nebulizer bowl filled with the reaction mixture, captures the aerosol particles and enters a quartz tube. The argon is then fed through a branch pipe to the high-temperature area. At an argon flow rate of 500 cubic centimeters per minute through a nebulizer, the alcohol flow rate is 0.2 cubic centimeters per minute. The flow of particles at the outlet is mixed with the excess flow of argon flowing around the nozzle.

The product is collected by passing a gas stream containing single-walled carbon nanotubes (SWCNT) through a filter with a pore size of 0.40 μm at the reactor outlet. The use of Ni2O3-Co2O3-Al2O3 catalyst during synthesis has a significant effect on accelerating the decomposition of hydrocarbons in the reactor and on the formation of carbon nanostructures at lower temperatures, leading to the production of higher quality carbon nanotubes. Although different sources can be used as carbon sources, the priority is to use methane because it does not decompose at temperatures up to 800 ° C, which makes it possible to obtain CNT with less amorphous carbon impurities.

Catalytic heat of methane led to the formation of multi-walled nanotubes (MWCNT) with a diameter of 30 nm with thin branches and dual structure in the low-temperature zone of the reactor.

UHMWPE has been selected for its good mechanical properties, good processability (thermoplastic), significant weight resistance ratio, and excellent energy absorption ability. In addition, the relatively low melting point of UHMWPE (~ 135 ° C) makes processing possible at relatively low temperatures.

To prepare CNT/UHMWPE composite fiber, UHMWPE particles and CNTs were mixed by triple abrasive with a treatment time of 6 hours to form CNT/UHMWPE composite particles. CNTs are spread evenly on the surface of UHMWPE powder without being cut short. The carbon nanotubes are evenly dispersed optically after the composite particle dissolves in decalin. By rotating the gel and hot stretching, the composite fiber is obtained. By regulating the epitaxial growth of UHMWPE on the surface of pristine CNTs, nano-hybrid shish-kebab (NHSK) with CNTs shish and UHMWPE kebab can be grown. This type of nanostructure can significantly improve the surface interaction between fillers and polymer matrices. Therefore, the amplification potential of nanofillers with a high image ratio (L / D) is achievable. Under more stretching, the kebab of UHMWPE becomes very wide chains along with fiber axis. After rotation, the hot stretching process increases the orientation, peeling, and mechanical properties of CNT / UHMWPE composite fibers.

b- Innovation:

Erosion and corrosion are serious challenges in oil and gas pipelines and cost the oil and gas industry billions of dollars every year. Environmental factors such as heat and chemicals can increase corrosion in pipes, leading to increased maintenance costs. One of the potentials of nanotechnology is nanocoatings to prevent corrosion and increase the durability of substrates. The startup plans to use carbon nanotubes to anti-corrosion coating oil and gas pipes.

Carbon nanotubes are one of the most important and widely used carbon structures recently discovered. They have unique properties and characteristics and high yang modulus, very high strength, and good flexibility and flexibility. The most important property of nanotubes is their electrical conductivity, which can be changed depending on the order of the atoms. They also have very high thermal conductivity. The high strength, durability, and excellent modulus of elasticity of carbon nanotubes are due to the sp2 bonds between the carbon atoms, making nanotubes the strongest and stiffest materials known for tensile strength elastic modulus. Under excessive tensile pressure, the nanotubes deform, which is a permanent deformation that starts at a pressure of about 5% and increases to the maximum pressure exerted on the nanotubes before cracking. Carbon nanotubes are very resilient and show good resistance to deformation and return to their original state by removing pressure from them without damaging their structure because they have few defects in their wall structure. Also, when they bend, the structure of the hexagonal rings in the wall changes but does not break. The most important physical property of nanotubes is their electrical and thermal conductivity. Each atom vibrates in its place, and when an electron (or electric charge) enters a set of atoms, the atoms vibrate more and transmit the applied electric charge when they collide with each other.

Various structures and equipment located in coastal areas and in the oceans, equipment used for the extraction and processing of oil, pumps, tanks, pipelines, machinery, and the like, which are made of steel and used in these industries, are exposed to corrosion. Therefore, in all these cases, CNTs anti-corrosion nanocoatings can be used to protect against corrosion and reduce its risks. These nanocoatings prevent the corrosion agents from reaching the metal substrate by providing a long path against oxygen and moisture.

Therefore, due to the higher efficiency and life and the need to apply a thinner layer for anti-corrosion nanocoatings containing carbon nanotubes, it is possible to deal with corrosion cheaper and more effectively. The steels used in the oil and gas industry operations must withstand saline water, fluids produced at each stage of the process, impact and wear, and various other factors that exacerbate corrosion. Anti-corrosion nanocoatings containing carbon nanotubes are very effective in such environments.

The pipelines work every day of the year. Computer performance allows pressure, flow, and energy consumption across the line to be constantly monitored. Computers can perform leak detection calculations quickly and take corrective action in emergencies, such as shutting off emergency valves, turning off pumps, and alerting repair crews (see also Computer Systems Programs). However, research shows that operating stations receive only 15 to 20 percent of pipeline leaks (https://www.thecanadianencyclopedia.ca). Companies still often use “discontinuous” detection systems, which include dogs and visual inspections, such as helicopter air surveillance.